How do you prepare your swimming pond for the winter?

Swimming ponds; ready for winter

Maintenance and cleaning

Precautionary actions

Nature lets go of her exuberant summer form and prepares for winter. The supply of blown-in dirt is now increasing. Work to be done for the (swimming) pond owner, everything that falls in has to come out! It’s also time to prune aquatic plants, maintain and winterize installed equipment.

Don’t wait to long, winter can already start with the first frost!

Well prepared for the winter results in a better start of the pond in the spring and prevents frost damage to pumps, filters, pipes and other installed devices.

AUTUMN WINTER FROST

Repeated cleaning tasks

Repeated cleaning tasks

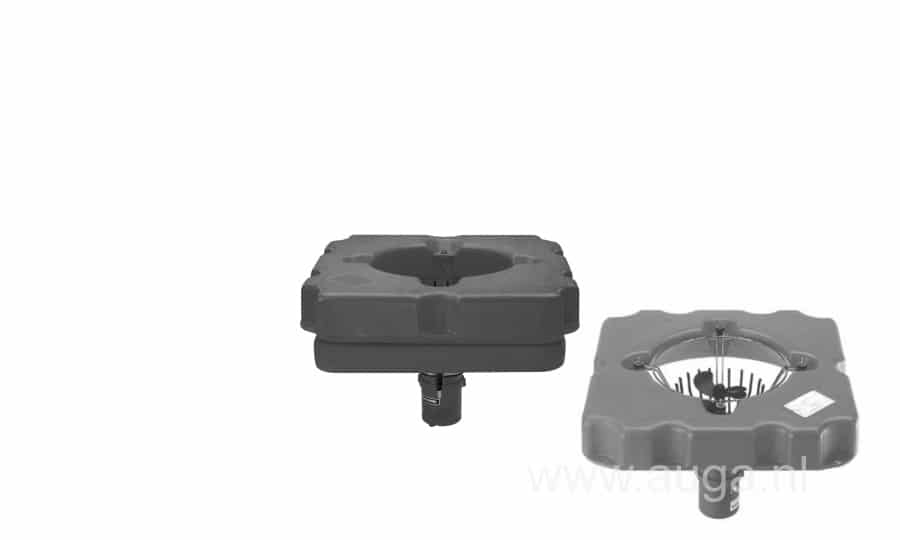

Skimmers, sieve filters, bottom and wall drains

Baskets of pond skimmers with regularity cleaning.

This applies to all suction points, such as suction baskets, bottom and wall drains, which are installed in the pond. Keep checking and cleaning as long as leaves fall into the pond.

Sieve filters are working overtime in the fall, because the amount of waste is high. This also applies to downflow heloft filters, which are placed near a pond. Keep checking and cleaning as long as leaves fall into the pond.

Cleaning the floor and walls

Removing plant and leaf residues on the bottom can be done very well with a pond vacuum cleaner. Cleaning deposits on pond walls.

Season end work

Season end work

Aquatic plants

Prune aquatic plants to 5-10 cm above water level, remove plant and leaf remnants from the swamp zone. If this remains, an excess of decaying material will arise, on which algae and seaweed will flourish.

The lava bed will be completely clean again in the spring by adding Bio Boost; a 100% natural mineral product with a strong biological activity, neutralizes acidity and restores the PH of the soil.algae and seaweed will flourish.

Water quality

Check the GH-value of the water, it should fluctuate around GH 12°. Fall and winter precipitation can acidify the pond environment and lower the GH-value. This is corrected with a GH+ agent. A GH-value that is too low is the cause of, among other things, algae growth.

Prevention against persistent frost

Prevention against persistent frost

With persistent frost there is a high risk of freezing and damage to all installed water-carrying devices and pipes. Preventive measures must be implemented now!

One option is to insulate pipes and appliances with insulating material, for example with bubble wrap, but that does not offer 100% certainty.

Since the entire biosystem is in hibernation, technology can usually be turned off.

System shutdown procedure:

- Switch off the entire system electrically.

- Close the taps of the supply and return pipes.

- Lower the water level in the swimming pond to below skimmers and/or other water supply systems, which are placed in the pond wall, in which water can be frozen.

- Remove water from all water-carrying appliances and pipes.

- Remove leakage/rainwater in a technical pit.

- Pipes and equipment may no longer fill with water, even during moderate rainfall.

When all existing technology is switched off, annual maintenance can be performed.

Equipment maintenance

Equipment maintenance

Pond pump

The water temperature drops, the capacity of pond pumps can decrease. This is easy with an adjustable pump and also saves energy and money!!

The pump will continue to operate as long as there is no risk of freezing. Running water benefits the bacterial culture in the plant filter, which survives the winter better and start up again faster in the spring.

UV-c device

The UV-c device is switched off, because it does not operate at low temperatures, which saves energy and extends the lamp life.

The lamp is filled with a special gas to induce UV-c aging. The operation of the lamp is strong after an average of 8,000 burning hours, because the gas – the “fuel” – is in the lamp. Autumn is therefore a good time to replace the UV-c lamp and clean the quartz glass according to regulations. Due to limescale on the glass the radiation effectiveness.

Make sure that the correct lamp power is placed back in the UV-c unit, the transformer of the device is adapted to this.

If there is no more water in the housing, it must not be removed.

Pressure filter

Remove the lid of the pressure filter with integrated filter foam pack from the housing, the pack may weigh heavily if the filter foam pack is strong. Clean according to instructions and store in a dry/frost-free place.

Remove residual water from the empty filter housing to prevent freezing.

Sieve filter

Thoroughly clean the stainless steel sieve at the front and back with a brush and replace it again, removing accumulated dirt in the housing. Remove residual water from the housing.

Drum sieve

Clean the sieve cloth and water nozzles. Remove residual water from the drum sieve.

Air pump

An air membrane pump draws in outside air, which is filtered by an air filter. This is mounted on or under the pump under a removable cover. Replace the air filter with a new one. With decreasing air capacity, the rubber diaphragms are worn, replace them. Store the air pump in a dry and moisture-free place

Remove air hoses that are above ground, if possible and store in a dry place.

Porous air stones cannot be cleaned. If the air flow decreases, it is wise to replace it, because the pump has to press harder and harder to pump air through the stones. The rubber diaphragms of the air pump wear out faster as a result.

Recessed lighting

Built-in wall lights stay in place, when ice builds up in the pond, ice pushes upwards and exerts much less lateral force. Removing algae from glass, swimming pond lighting is very atmospheric in winter.

Water supply

The water replenishment can be shut off to avoid freezing of the tap/float pipe. Remove residual water from pipe and float housing.

Do you want to know more? Contact AUGA